Fugitive EtO abatement throughout the supply chain—from origin to destination.

EtO fugitives are a moving target. Sonata’s ductless, mobile Helios™ system moves with them, eliminating them at the source as they travel through the post-aeration supply chain. From transport, warehousing, and distribution centers to delivery, Helios is with you every step of the way. Extend the post-aeration stage, ensuring safety and compliance without interrupting the flow of goods.

Sterilization facility

Add Helios to post aeration rooms (“Group 2”) and common areas like office spaces, control rooms, and labs, to capture EtO fugitives and ensure worker safety and facility compliance

Transportation

Sterilized medical devices can be containerized and shipped sooner when accompanied by a Helios system that removes EtO fugitives

Distribution centers

Place Helios next to post-aerated “hot pallets” to reduce the risk of off-gassing EtO. Helios stops EtO where it starts, keeping workers and communities safe—inside and out

Helios doesn’t just capture fugitives. It destroys them.

Sonata’s Helios product line provides a total system solution to combat EtO and EtO-generated by-products like acetaldehyde, all in a single, ductless unit. A proprietary catalyst uses light instead of heat to oxidize EtO fugitives and related organic volatiles on the spot, converting them to harmless CO2 and water. Deliver clean air everywhere you use Helios.

With Helios, there’s no place to hide.

As EtO fugitives escape, they seep through walls and hide throughout the facility, even in rooms far from sterilization bays and aeration areas. These fugitives harm workers and make facilities non-compliant. EtO diffusion and HVAC design can limit the ability to abate workplace fugitives. Helios provides the first cost-effective solution designed to eliminate EtO fugitives in nearby rooms, meeting the challenge of keeping facilities safe behind every door. (Diagram courtesy of Picarro)

Simple. Portable. Fits in anywhere.

The Helios unit is self-contained and mobile. It’s plug and play with a rapid start-up. No expensive facilitization or recertification. No natural gas or heating. It fits in anywhere. It enables flexible implementation in post-aeration environments, including intermodal transport. Ship sooner, safely. It is the only EtO solution specifically designed to eliminate EtO fugitives where they originate with no infrastructure investment.

Proven in real-world scenarios.

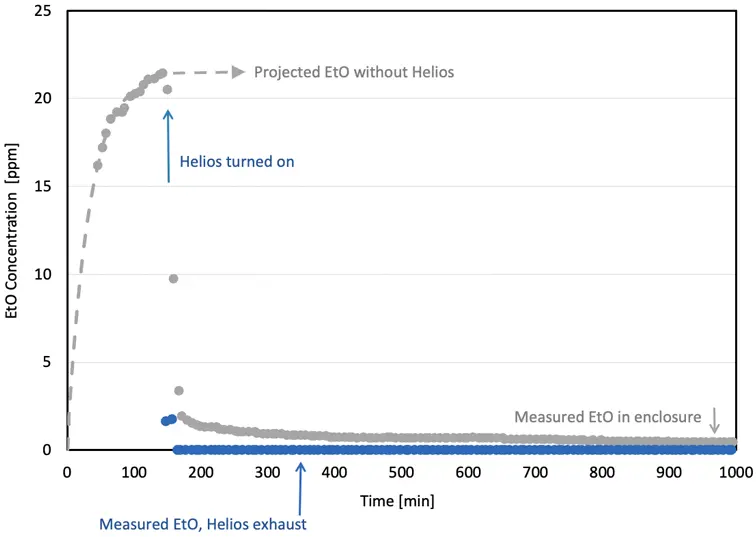

Testing in sterilization facilities confirms Helios’ performance. Helios rapidly reduced EtO fugitives off-gassed from a recently aerated pallet staged in a temporary enclosure. EtO DRE was 99+%, with less than 10 ppb EtO in the air exhausted into the wider environment (blue data markers). EtO levels in the enclosure were reduced from 20 ppm to below 300 ppb, and these low levels were maintained as the pallet continued to off-gas (gray data markers). Helios works even when the air matrix is complicated by other common contaminants, from CO2 to water vapor to cleaning agents. It performs under a wide variety of environmental conditions, including relative humidity (RH) from 20%-70% and temperatures 40-80 °F.

Download Picarro-Sonata Scientific white paper

Download Helios MP-500 data sheet

EtO-free air. Now available everywhere.

Helios polishes the air, removing health risks and making clean, EtO-free air both in the sterilization facility and at all points along the supply chain. Your staff can count on clean air everywhere in your workplace—from office to warehouse. Compliance with new regulations is facilitated by achieving ultralow EtO levels indoors. Fugitive-free air is assured when shipments leave your facility—from trucks to distribution centers to the community at large.